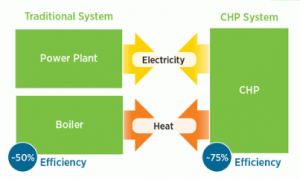

With historically low natural gas prices and financial incentives, many large energy users are turning to combined heat and power (CHP) or cogeneration plants to reduce energy costs, lower their carbon footprint, and improve the reliability of their power supply. CHP is a way of creating on-site electricity with natural gas or bio-gas and capturing the waste heat from the exhaust and using it for useful thermal energy in space heating, domestic hot water, industrial processes, and cooling. Nearly two thirds of the energy used by traditional electric generation plants is wasted in heat discharged to the atmosphere. CHP is a more efficient way of creating on site energy with the ability to achieve efficiencies of up to 85% by utilizing the wasted heat, compared to the 50% efficiency of traditional approaches of buying power from the grid and using a boiler for hot water.

CHP benefits to customers include:

Economic Benefits

Since CHP is a more efficient way of generating energy for a facility, it can save a considerable amount of money in energy bills. The waste heat produced by the system can offset the fuel costs from boilers and chillers while the power generated by the system is often less expensive than purchased electricity from the grid. With less electricity purchased from the grid, facilities will have less exposure to rate increases and have protection of future revenue streams. In addition, CHP can help with avoided capital costs since it will reduce future costs of purchasing boilers, chillers, and backup generators.

Reliability Benefits

Electric grid outages have increased significantly over the past 20 years and cost more than $30 billion a year. CHP systems can provide power in emergency situations such as storms, security breaches, and grid overloads. CHP allows buildings to become more resilient and mitigate impacts of an emergency by creating their own electricity, hot water, chilled water, and steam on-site. Furthermore, CHP can be the backbone of a microgrid and run in parallel with other technologies like solar, wind, and batteries providing power to critical infrastructure like hospitals, waster water treatment, and the military at times when they need it the most.

Environmental Benefits

Since CHP systems use less fuel than the traditional approach of buying grid power and producing thermal energy on-site, facilities will significantly cut their carbon footprint the day they turn on their CHP system ¾ while also increasing their sustainability efforts.

The process towards a CHP project with Pennoni is simple when following these steps.

- Feasibility

Pennoni will conduct a site assessment to determine the financial, operational, and environmental benefits a CHP unit can provide. The CHP feasibility considers site-specific issues that will affect the system along with the existing infrastructure. The study will conclude with an energy and financial model for the customer.

- Rebates & Incentives

Pennoni will determine what state, federal, and local utility incentives may be available for the project. Once incentives are identified, Pennoni will apply on the facility’s behalf. CHP incentives can significantly lower upfront capital costs for the client. Listed below are a sample of rebates and incentives Pennoni has secured for their clients over the past year.

|

Current CHP Incentives Pennoni has secured |

|

|

Chemical Manufacturing Plant |

$1,250,000 |

|

Higher Education Facility |

$500,000 |

|

Biogas Plant |

$500,000 |

- Identify Prime Mover

Pennoni will conduct a study to determine which prime mover or power generation technology makes the most economical and operational sense for the client. Examples of technologies include: gas turbines, microturbines, reciprocating engines, and fuel cells.

- Finance Options

Multiple options for financing a CHP system are available to clients, like a capital purchase or a third-party ownership model. Third party ownership models can be an Energy Service Agreement or Power Purchase Agreement, where no upfront capital is required from the client. The client saves money as the system produces energy.

- Engineer Procure Construct

The final step to implementing a CHP project is the engineering, procurement of equipment and construction, otherwise known as EPC. Pennoni’s engineering-led design-build team allows the client to realize a true turnkey delivery of the project.

Michael Cromer, PG, DBIA, ENV SP

Michael Cromer, PG, DBIA, ENV SP

Mike serves as Associate Vice President and Regional Vice President for the Energy and Design-Build region. He has spearheaded the development of distributed generation, compressed natural gas (CNG) and Combined Heat and Power (CHP) business models providing diversification and additional revenue streams.