As more states legalize cannabis for both medical and recreational use, facility owners and developers across the country are grappling with decisions related to the development of indoor agriculture facilities that have extremely high energy requirements and a demand for resiliency.

These facilities require power for lighting, heating, cooling and dehumidification. And it is their extremely high energy requirements for both reliable onsite electricity and chilled water that makes them prime candidates for the use of alternative energy solutions, such as combined heat and power (CHP).

As part of a Design-Build team led by to E-Finity Distributed Generation, LLC, Pennoni provided design and grant writing services for a new state-of-the-art indoor grow facility in Jessup, MD. Project development and third-party financing were provided by NgenX, a national energy solutions developer, partnered with Scale Microgrid Solutions. Scale Microgrid Solutions builds and finances distributed energy projects across the United States and Caribbean, for commercial and industrial customers.

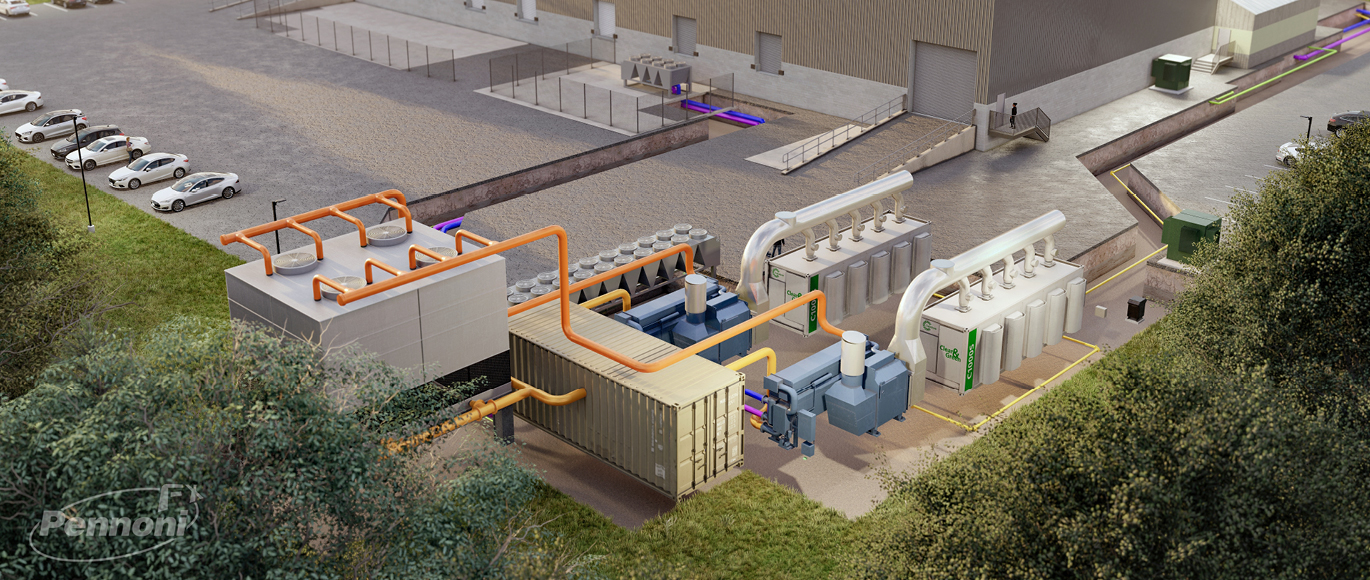

Pennoni’s mechanical and electrical engineers led the design of a new combined heat and power (CHP) cogeneration system to provide on-site electric generation that utilizes the byproduct heat for climate control in the grow rooms. Construction of the CHP project began earlier this year and is equipped with two 1-MW Capstone microturbines.

The heat from the microturbines is recovered to produce chilled water through an absorption chiller that is in turn used for dehumidification and cooling of the grow facility. These microturbine generators provide primary power and backup generation, allowing power and cooling to remain available should the power grid go down. This resilient design provides protection against crop loss, while reducing operating cost.

Having heating and cooling that operate independently of the grid is crucial in the event of power outages. Power outages can be devastating to crops. In regular outages, growers have little time before crops become effected.

Pennoni worked tirelessly, with the NgenX, to bring this project from start to finish, from concept to cash flow modeling to grant services from both the state and local utility.

The grow facility is on track to be finished by the Fall of 2022 and thanks to the use of CHP technology, will be supplied with an always-on, cost-efficient, resilient, low emissions power source and capable of standalone operation. As Pennoni continues to strive for a more sustainable future, projects like this resilient indoor agriculture facility help pave the way.

For more information on our energy and sustainability service offerings, contact Mike Cromer.